3D printing has the potential to bring the power of blueprint and manufacturing to the hands of common Indians

The Chinese invented the movable type some 1,000 years back. Three hundred years later the Korean calligraphers and printers had refined the moulding technique enough to introduce metallic movable type, the first of its kind in the world. Contrary to popular perception, Johannes Gutenberg is not the inventor of the metallic movable type. Neither is he the first one to have independently invented the mechanical printing press. Bits and pieces of design and various parts had travelled to Europe from the Arab world and Asia.

Gutenberg’s singularly original contribution was the invention of a process by which movable type was mass-produced in a standard manner using an alloy of lead, tin and antimony. Such has been the simplicity and robustness of the technique that it’s still the foundation of all analogue printing technology. Again, contrary to the common historical narrative, the reason why mechanical movable type became so successful in Europe was not just due to the rapid proliferation of the technology and its extensive use by the Church to propagate the Bible.

One of the critical understated reasons was the simplicity of the European language, especially in terms of tenses and alphabets, in comparison to Korean and Chinese languages. In short, the German, French or English, to use a digital phraseology, had the finiteness of meaning and structure to be turned into a typology blueprint.

And therein lies the future of another printing revolution unfolding before us. It is aided and abetted in no small measure by a set of digital technologies. 3D printing, often referred to as additive manufacturing, is already doing what Guttenberg did to the foundation of modern economy by the widespread use and circulation of paper money. Conventional wisdom will always tie Guttenberg with printing technology.

But his real contribution was the way our notions and practice of business, social and economic transactions and daily life was radically transformed. The reason why such a transformation was able to take place was the ability of the printing technology to accommodate standardised blueprints: one rupee could be printed again and again.

Say your son or daughter wants a remote-controlled toy helicopter as a gift that he or she has seen with a friend. A typical delivery cycle will be something like this: a set of different factories, most probably in China, will have massive machines and moulds churning out different parts of the toy helicopter from rotor blades, transmission switches, receivers, electric engines and the brain. Another factory, again in China probably, will be putting all the parts together, doing quality checks, packing and labelling them. The factory will then ship off batches of helicopters to various wholesalers and large marts across the world. These will then be sent to various shops and e-commerce warehouses. You, as a father, will either go to a shop to buy the toy or, more likely, place your order with the e-commerce sites. The helicopter will eventually be used by your son and daughter and probably be proudly shown off to their friends. It’s not just the interlinked factories, shipping companies or the logistical management practices that has ensured that the exact same helicopter landed up at your doorstep. The real magic and miracle is the blueprint for the helicopter that made it possible to produce as many copies as possible.

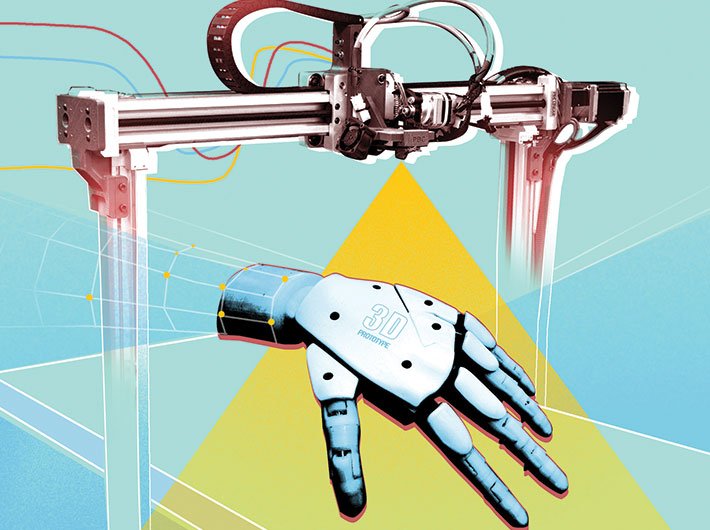

3D printing puts the power of the blueprint right in your hands. In the near future it can actually take the factory and the manufacturing out of the economic ecosystem. Currently the machines are fairly expensive and can work only with a few materials. Its main application has been in the field of rapid prototyping in mechanical and automotive engineering, though it’s increasingly entering more intricate and design-heavy areas like architecture, fine arts and jewellery. The most interesting set of developments are happening in the area of healthcare and artificial organ creation with 3D printers being used to create organs ranging from ears to liver. It’s precisely these developments that show the future potential of 3D printing. With reference to India, especially within the framework of Make in India policies, 3D printing can bring about three clear advantages to the Indian economy.

The first is the decentralised and democratised availability of tools and resources that otherwise would have had to come through the torturous route of bureaucratic procurement or skewed market dynamics. A typical example could be a doctor in a rural area printing critical but simple medical equipments like disposable syringes or autoclaves.

The second is the strengthening of innovation at the level of design and blueprints. India already has a strong and robust training infrastructure for all kinds of industrial, hardware and software design and plans. In conjunction with the open-source community, India can easily become the hub for low cost, customised and high efficiency designs and blueprints that takes care of local resources and needs.

The third is a clear reduction of environmental and ecological footprint that comes from large factories, storage hubs and use of materials, electricity and natural resources in an exploitative manner. The case for how small, decentralised and locally specific models of development lead to lower carbon footprint while resulting in deeper and engaged well being of people is clearly established.

Investing in 3D printing technologies and scaling it up may not be a bad idea for India. It’s a technology that’s not yet fully established, though its potential for social and economic transformation is phenomenal. It’s this potential that India should explore.

(The column appears in the September 1-15, 2015 issue)