As the Make in India gathers momentum, it is important to see it doesn’t rush onto a route that has a snarl ahead

Years after the Nano car was launched, Ratan Tata was quoted in the media as saying it was a mistake to position it as the “cheapest car” (rather than perhaps highlighting its other attributes like fuel efficiency, ease-of-maneuvering, design, et al). The cheapest car ‘stigma’ took much time to go away even after the car as well as its positioning was refreshed to deliver a more contemporary feel.

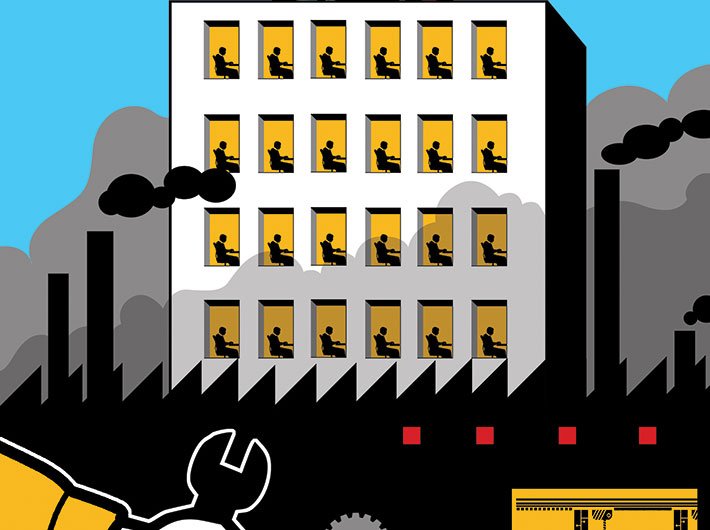

The current positioning of the Make in India campaign borders on facing a similar risk and may be in need of some steering-away from a potential danger zone. Experts, of late, have been suggesting that the government should be careful not to overly focus on getting global companies to set up “low-cost” hardware factories in the country. Instead, there could be much greater value in attracting investors to set up, say, design and innovation centres in India.

Leverage China selectively, not compete with it

In an open-market economy, where ultra-cheap finished goods flow freely from China to India (as also to other markets globally), it is the market forces that determine the staying power of a manufacturer. Chinese manufacturers have attained economies of scale that give them an advantage which is hard to match for Indian manufacturers, until the government intervenes in a supportive manner.

The question is how far a government can support, especially in a given scenario where China is having an inventory pile-up and may choose to further cut prices in order to keep its manufacturing-based economy moving. As a parallel, Saudi Arabia’s stand on oil production has been pressuring shale oil rigs in the US and rendering them uncompetitive. What would stop China from doing something similar to thwart competitions across its global markets, including India?

China, with its globally leading foreign exchange reserve estimated at more than $3.7 trillion, certainly has much more staying power than India, which has forex reserves of just over $350 million – less than one-tenth of China’s.

By trying to compete with China in areas of manufacturing where it has a stronghold, India could end up locking its energies and resources in what could at best become very low margin businesses.

Instead, India could benefit more by building upon its existing strengths in service sectors, particularly since the current advancements in digitisation and automation very much make it possible to productise services (conversely, products are already being offered as services).

India’s service sectors, especially of the ICT genres, have already reached such high levels of maturity that productising by way of automating and digitising the processes would actually be a next logical step. That would also give India the differentiating edge that it has so far maintained but risks losing as other IT service destinations like Philippines and Ireland try to catch up.

At the same time, India could continue to build upon its manufacturing strengths in areas like automobiles, processed food products and the new-found hi-tech areas like satellite launchers (and again, also in the area of satellite launching as a service!).

China has a surplus that India doesn’t have

More often than not, manufacturing plants draw heavily upon infrastructure resources like power and natural resources like water, both of which are already scarce in India, which still heavily depends on successful monsoons for replenishing much of its water resources that also help meet a significant chunk of its hydropower generation needs.

While India is still ranked fifth in terms of its hydropower generation potential, hydropower’s contribution to overall power generation has dwindled from about 46 percent in the mid-sixties to around 15 percent at present. Moreover, ground water levels across several Indian cities have been receding to alarming levels and leading to severe water crisis situations.

While India’s population is comparable with that of China, its geographical coverage is less than one-fourth of the latter. China is also home to the world’s third and sixth-longest rivers – Yangtze and Yellow River – both of which are more than double the length of the Ganges, which is the longest river flow in India.

Yet, China is experiencing severe environmental issues, including air and water pollution and shortages despite having committed hundreds of billions of dollars towards water infrastructure and desalination projects spanning multiple years. As the world’s second largest economy and with a globally leading forex chest, while China may be able to tide over its resource woes, India simply won’t have the funds of such mega scales at its disposal.

It’s about doing it sustainably — and doing it smartly

That’s a lesson to be learnt from China, which by virtue of its first mover advantage as the world’s first shop floor, was able to build a financial strength from where it could invest back into correcting the damages done to its environment. India doesn’t have such an advantage, and without that it would be hard to attain a position of comparable financial strength. The cost of environmental damage could become irreparable in that case.

An answer to the problem could potentially lie in taking a 360-degree approach to programmes such as the 100 smart cities. By making conservation of environmental resources a pivotal and ground-up aspect of such programmes, India could start preparing itself for long and sustainable innings in various sectors of manufacturing.

Moreover, there is a need to rethink and revisit the manufacturing processes across various industries so as to remove inefficiencies and make those more environment-friendly. The government could play an important role in this context, say, by setting up a nodal agency that sets itself the task of ideating and identifying best practices from across various industries globally and porting those to other industries as well.

The Make in India campaign has been marketed well and has also been received well so far. By integrating it with programmes like smart cities, the gains could further be concretised. Moreover, India would only be sending out the right signals to potential investors and also making sure that fly-by-night manufacturing ideas are discouraged and thwarted while the sustainable ones are planted and nurtured towards mutually beneficial goals.