The railways has decided to go for LHB coaches, designed not to topple or telescope into each other during a collision. The Raebareli coach factory, where they are made, has a hectic schedule

Since November last year, India has witnessed three horrible railway accidents, two near Kanpur and one in Andhra Pradesh. They claimed more than 200 lives. Railway experts feel the casualties could have been far fewer had Linke Hofmann Busch (LHB) carriages been used on the trains instead of conventional ones: LHB coaches have comprehensive safety features that prevent carriages from telescoping into each other should a derailment happen. They are also designed to reduce the chances of their capsizing.

In the railway budget of 2015-16, it was decided to end the manufacturing of conventional coaches 2018 onward. It was also decided to increase production of LHB carriages and retrofit conventional coaches to improve safety features. But progress was slow. For the 2016 fiscal, a target of 1,697 LHB coaches was set; 1,000 have already been built. The target is for 3,025 more in 2018-19 and 3,349 in 2019-20.

LHB coaches, based on German technology, are manufactured at the Rail Coach Factory in Kapurthala, Punjab; the Integral Coach Factory (ICF), Perambur, Tamil Nadu; and the Modern Coach Factory (MCF), Raebareli, Uttar Pradesh. The former two also make conventional coaches, while the one in Raebareli, renamed in December 2015, manufactures only LHB coaches, up to 1,000 per year.

All in the links

Robotics and laser-cutting technology allows MCF to produce the coaches at an efficient pace and with few errors. The factory floor has four major shops: for shell making; coach fabrication; wheel assembly; and blasting, painting and furnishing. In the first, stainless steel sheets, which come in rolls, are flattened and formed into the sides and roof of carriages. A robot cuts out window openings with a laser. Once this shell is ready, it’s fitted onto a base. It’s taken to the coach fabrication, wheel assembly and painting and furnishing shops. Safety and other tests are performed on the completed carriage before it is declared fit for use. Once ready, rakes of 18-22 coaches each are dispatched from the factory. It costs Rs 2 crore-2.5 crore to produce each LHB coach, against Rs 1 crore-1.5 crore for the usual one.

The chief difference is the centre buffer couplers (CBCs) used to join coaches into rakes. “These couplers are anti-telescopic, which means coaches don’t topple in case there is collision or derailment,” says Jogendra Meena, manager of the bogie shop. “Also, the coaches are made of stainless steel, which makes them lighter than conventional coaches. An improved suspension system ensures riding comfort.”

LHB coaches arrived after the Indian railways signed a transfer of technology (ToT) agreement with German firm Linke Hofmann Busch in 1996. These coaches are being manufactured at the Kapurthala factory since 2001 for use in Rajdhani express trains. Says an official, “Production requires ultra-modern technology and thorough precision. LHB coaches offer two metres more space than conventional coaches, making for eight additional berths in AC three-tier carriages. They can be run at 160-200 kmph.”

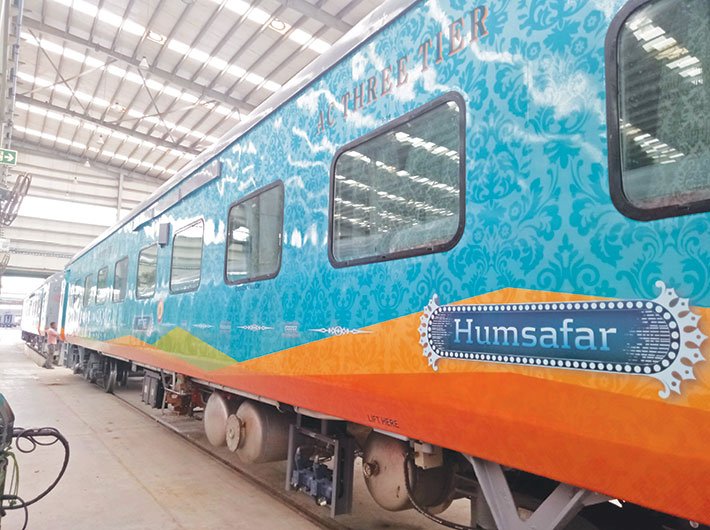

The Raebareli factory unveiled the first rake of Humsafar Express, comprising LHB AC three-tier coaches on November 12, 2016. Four other such rakes would be rolled out this year. The Humsafar Express coaches are equipped with GPS-enabled information display board, tea and coffee vending machines, CCTV cameras, fireproof curtains and charging points. Premium trains like Rajdhani, Shatabdi and Gatimaan also have LHB coaches.

The MCF has a production schedule to manufacture two rakes of second class general coaches for Antyodaya expresses. Since it started making them, the MCF has rolled out 1,005 LHB carriages: 18 in 2011-12; 70 in 2012-13, 130 in 2013-14; 140 in 2014-15; 285 in 2015-16 and 362 in 2016-17 (till December 2016). Mahesh Kumar Gupta, general manager of the MCF, says efforts are on to speed up production to meet the requirements of the railways. Pending with the railway ministry is a proposal for the MCF to manufacture metro coaches with expertise from the railways’ research, design and standards organisation (RDSO) in Lucknow. Also, next fiscal onward, the factory will manufacture generator cars.

Safety steps

After budget 2017-18 was presented, railways minister Suresh Prabhu said at a press meet that it would take a few years to fully stop the manufacturing of conventional coaches. He, however, said that the existing conventional coaches are being retrofitted with CBCs to make them safer. There are 45,000 of them, and they are to be retrofitted over the next three-four years.

Also, the government approved the creation of five-year Rashtriya Rail Sanraksha Kosh (RRSK), a trillion-rupee fund for rail safety. It is looking to spend Rs 20,000 crore annually for track renewal, repair and rebuilding of old bridges, maintenance work and other safety measures.

Switching to LHB coaches from 2018 fiscal and retrofitting existing coaches, both are easier said than done. As many as 1,330 conventional carriages have been manufactured by RCF Kapurthala and ICF Chennai this fiscal. Many senior railway officials doubt whether replacement of conventional coaches with German carriages by 2018 fiscal will be possible. According to them, it would take another 20 years to completely switch to LHB coaches both for AC and non-AC category.

Eco-friendly factory

The MCF is also marked out by the eco-friendly initiatives it has undertaken. It has a 2 MW solar plant (the biggest in any railway establishment), wind-powered exhaust fans, a sewage treatment plant, and a vast network of LED lights. ‘Cool daylight’ bulbs light the factory floor, keeping the temperature four degrees celsius lower than with normal lighting. The MCF is also planning to have a rainwater harvesting plant.

vishwas@governancenow.com

(The story appears in the April 1-15, 2017 issue of Governance Now)